What are the minimum requirements for use of rubber goods?

OSHA, ASTM and NFPA standards require the use and testing of in-service rubber insulating equipment when even the smallest probability of contact (50 volts AC or higher) exists. Insulating gloves and sleeves are critical PPE for electrical work on or near exposed energized parts. The OSHA 29CFR 1910.269 standard requires that rubber insulating gloves along with leather protectors must be worn by 269-qualified employees within the Minimum Approach Distance to exposed energized conductors. Additionally, rubber insulating sleeves must also be worn if the upper arms or shoulders are within the Minimum Approach Distance to other exposed energized parts.

How do I determine the right class of rubber insulating gloves?

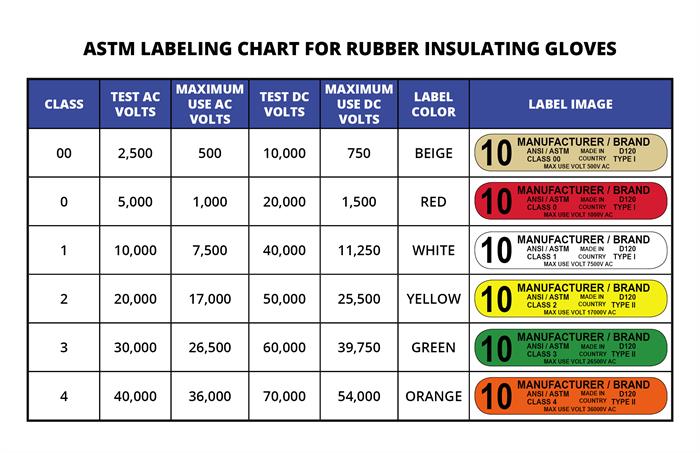

According to OSHA Regulations 29CFR 1910.137, rubber insulating gloves must be rated for the voltage to which a worker will be exposed (phase to ground or phase to phase) and marked to indicate their rating. Electrical protective gloves are categorized by the level of voltage protection they provide. Voltage protection is broken down into the following classes, and each class of gloves is clearly marked with the maximum use voltage on the permanent color-coded label:

- Class 00 - BEIGE LABEL

- Maximum use voltage of 500 volts AC/proof tested to 2,500 volts AC

- Maximum use voltage of 750 volts DC/proof tested to 10,000 volts DC

- Class 0 - RED LABEL

- Maximum use voltage of 1,000 volts AC/proof tested to 5,000 volts AC

- Maximum use voltage of 1,500 volts DC/proof tested to 20,000 volts DC

- Class 1 - WHITE LABEL

- Maximum use voltage of 7,500 volts AC/proof tested to 10,000 volts AC

- Maximum use voltage of 11,250 volts DC/proof tested to 40,000 volts DC

- Class 2 - YELLOW LABEL

- Maximum use voltage of 17,000 volts AC/proof tested to 20,000 volts AC

- Maximum use voltage of 25,500 volts DC/proof tested to 50,000 volts DC

- Class 3 - GREEN LABEL

- Maximum use voltage of 26,500 volts AC/proof tested to 30,000 volts AC

- Maximum use voltage of 39,750 volts DC/proof tested to 60,000 volts DC

- Class 4 - ORANGE LABEL

- Maximum use voltage of 36,000 volts AC/proof tested to 40,000 volts AC

- Maximum use voltage of 54,000 volts DC/proof tested to 70,000 volts DC

What are the applicable OSHA regulations concerning in-service testing of rubber insulating products?

29CFR1910.137(b) covers in-service care and use of electrical protective equipment, specifically insulating blankets, covers, line hose, gloves, and sleeves made of rubber and specifically references the relevant ASTM specifications.

What ASTM specifications apply to the in-service care of rubber insulating products?

- ASTM F 478-xx (Insulating Line Hose and Covers)

- ASTM F 479-xx (Insulating Blankets)

- ASTM F 496-xx (Insulating Gloves and Sleeves)

The “xx” refers to the year that the standard specification was most recently approved.

What are the testing intervals for rubber insulating products?

The interval between date of issue and tests should be based on work practices and test experience. For gloves, the interval shall not exceed 6 months except for industries such as telecommunications that utilize insulating gloves as precautionary protection, in which case the maximum interval may be increased to 9 months. For sleeves and blankets, the interval shall not exceed 12 months. For line hose and covers, no maximum interval is specified; electrical testing shall be performed if the periodic cleaning and visual inspection identifies conditions that might adversely affect performance and safety.

How do I know if I need AC or DC testing for my rubber insulating products?

For maximum safety, it is important to understand the application for use and test the rubber insulating PPE as close as possible to that environment. While AC testing is applicable for general use, DC (direct current) testing is necessary for rubber insulating products in applications where there is exposure to DC, including (but not limited to) electric vehicles (EV), both fully electric and pulg-in hybrid, renewable power generation (wind and solar particularly) and electrified mass transit and transportation. Click here to learn more about Voltgard's DC testing services.

What about retesting unused rubber insulating products?

All electrical protective rubber insulating products are tested by the manufacturer prior to first shipment. End users (or an end users’ designee) may perform acceptance testing within the first 2 months after receipt. Rubber insulating products shall not be placed into service unless they have been tested electrically within the previous 12 months.

What is involved in the inspection and testing process?

According to ASTM specifications, at a minimum the inspection and testing of rubber insulating products includes check-in, removing previous testing marking, washing using cleaning agents that will not degrade the insulating properties, visual inspection of all surfaces (inside and out), electrical testing at either AC (alternating current) or DC (direct current) voltages depending on the application, final inspection, recordkeeping, marking, and packing in appropriate containers for storage or shipment. “Appropriate containers” means boxes, or similar sturdy packaging materials to prevent folding, creasing, or similar loose storage that can cause stress on the rubber.

Can rubber insulating products be repaired?

While some test labs will perform repairs or trims on rubber insulating equipment, it is generally not a good practice. The best approach to ensuring electrical safety after identifying a defective or damaged rubber insulating product is to replace it with an electrically-tested and approved product. The Voltgard Test Lab does not believe that repairing or trimming defective rubber insulating products is a good practice and such repairs will not be performed.

Who is qualified to perform in-service inspection and testing of rubber insulating products?

Many electric power utilities operate their own dielectric test facility to perform acceptance and in-service testing of rubber insulating products. There are also independent testing facilities that can perform the acceptance and in-service testing on behalf of end users.

What is “NAIL” and what does it mean to be a NAIL-accredited test lab?

NAIL (or formally NAIL4PET) stands for National Association of Independent Laboratories for Protective Equipment Testing. It incorporates the only Laboratory Accreditation for the electrical equipment test labs program in North America. Accreditation criteria include laboratory facility, equipment, training and knowledge of staff and quality control work procedures covering the inspection and testing of electrical protective equipment in accordance with ASTM specifications. Today the NAIL program is recognized throughout North America as an important asset to the credentials of a testing facility.

Why should I test my old rubber insulating gloves when I can just purchase new goods?

Throwing away your rubber insulating gloves, when you can potentially retest and recertify them by a qualified test lab, is like throwing money down the drain. For example, why spend $200 every 6 months to replace a pair of high-voltage gloves when you can test the gloves for less than 10% of that without sacrificing safety or compliance?

- Maximum use voltage of 26,500 volts AC/proof tested to 30,000 volts AC

- Maximum use voltage of 39,750 volts DC/proof tested to 60,000 volts DC

Click here to access the Voltgard® Rubber Insulating Products Testing Order Forms to get started.